3 min read

Building a Cannabis Facility from the Ground Up

Dialectic Engineering

Apr 20, 2023 4:00:00 PM

Since the 1970s, public opinion on cannabis has shifted dramatically. Until recently, it had been an illegal substance across the entire United States, used primarily for recreational purposes and sometimes in medical or religious contexts – though this was often not recognized by the law. The 2000s saw more regulations being put into place to control the cultivation, sale and use of marijuana. These have allowed for the growth of the medical marijuana industry and, more recently, the recreational marijuana industry.

As of March 2023, 21 states and the District of Columbia have legalized recreational cannabis and 39 states and the District of Columbia have legalized medicinal marijuana. As cannabis has become more commercially viable, an entire industry has quickly developed around it. From regulation lobbying to logistics and marketing, the cannabis industry is growing each day. Much like agriculture, the cannabis industry has seen improvements in its grow facilities to create a more reliable and consistent product. Chemists, herbologists, engineers and business developers work together to create cannabis grow facilities that are continuously improving.

What Makes a Good Grow Facility?

Mechanical, Electrical and Plumbing (MEP) Engineering Partners

Working with an MEP engineering partner will help in the planning, installation and maintenance of the necessary systems and controls that enable you to grow a reliable and consistent cannabis product. By implementing custom-built MEP systems from the vegetation room to the drying room, your grow facility is sure to produce as expected. With the high-level technology available in grow facilities, MEP engineering partners can quickly adapt your unique solutions for success.

Scaling Your Cannabis Grow Facility

For decades, cannabis cultivation has been concealed, and outdoor growth practices have been tailored to external growth factors like weather. When trying to get a new commercial grow facility up and running, growers often fail to plan for business growth, leading to issues as they expand their operations. With a trusted MEP partner, cannabis suppliers avoid these growing pains while looking ahead to the future of your business. Your MEP partner should be ahead of industry trends and aware of commonly encountered errors in indoor grow facility projects. They will help you develop your commercial grow facility with future growth and innovation outlined in their plans.

Controlling Your Grow Facility Climate

While conventional growing methods may be effective for small-scale operations, they do not account for a variety of external factors that decrease profits and lead to problems. When creating a product for open market sale, consistency is key. While external lighting, temperature and humidity levels can vary, conditions in your indoor facility can be manipulated at any time so you can optimize your product.

Grow Facility Temperature Control

Temperature control is essential to a successful cannabis grow facility. It needs to remain consistent throughout the grow process, between 70-80 degrees Fahrenheit. Proper insulation and climate control measures such as air conditioners or heaters ensure a stable temperature for a grow facility.

Grow Facility Humidity Control

Humidity in cannabis grow facilities should remain between 40-60 percent. To ensure this, it is important to have proper insulation and ventilation in place. Additionally, strategically positioned dehumidifiers can be used as needed to control humidity levels. Finally, keeping track of the moisture content of the soil and watering plants as needed is essential to maintain ideal humidity levels throughout the grow facility.

Grow Facility Lighting Control

Cannabis plants need at least 8-12 hours of light a day. Metal halide lamps are often used in grow facility setups, as they provide the necessary intensity and UV spectrum for optimal growth. Additionally, LED lights can also be used to provide plants with adequate lighting for growth.

Grow Facility Air Control

To ensure that plants are receiving the right amount of oxygen, airflow is essential in any cannabis grow facility. Proper ventilation should be implemented to keep air circulation at optimal levels and prevent humidity build-up which can cause mold or other problems. Fans and air conditioning units can be used to keep air moving at a consistent velocity and volume, while open windows or skylights can be utilized to increase natural airflow.

Grow Facility Drainage

Consistent water and reliable drainage are essential for any cannabis grow facility. Plumbing needs to be in place to allow for plant irrigation as well as proper excess water drainage. Additionally, a filtration system may be necessary to ensure that the water being used is free of contaminants or other impurities.

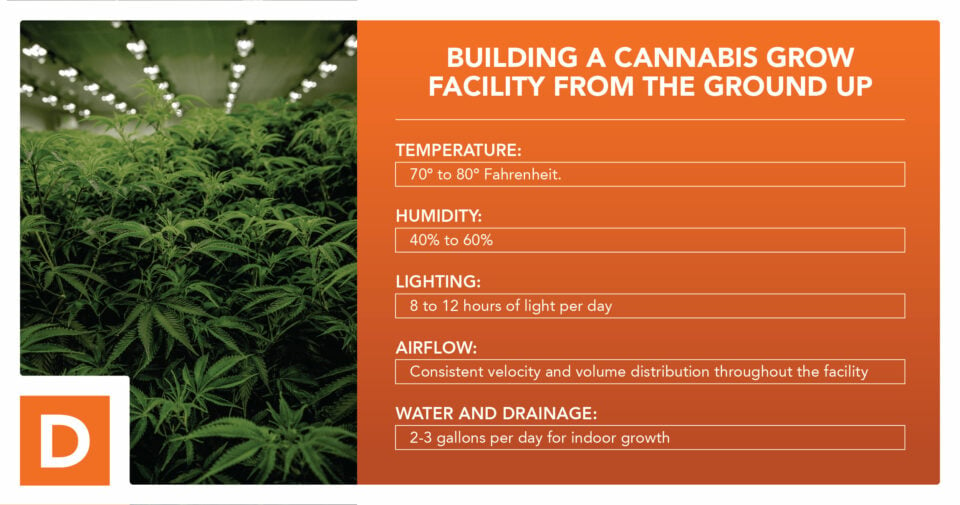

Temperature – 70-80º Fahrenheit.

Humidity – 40-60%

Lighting – 8-12 hours of light per day

Airflow – Consistent velocity and volume distribution throughout the facility

Water and Drainage – 2-3 gallons per day for indoor growth

Who Builds Cannabis Grow Facilities?

With all the variables that can impact cannabis production such as lighting, temperature and humidity control, there’s a lot that has to happen behind the scenes to ensure a high-quality crop. That’s why you need a good MEP engineering partner by your side to help guide the design of your facility. MEP engineers are experts in the systems needed to create an optimized cannabis product. They partner with cannabis production business owners to understand their specific needs and develop state-of-the-art grow facilities.

How Can Dialectic Engineering Help Build a Grow Facility From the Ground Up?

At Dialectic Engineering, we have developed more than a dozen dedicated cannabis grow facilities, from the early days of medical legalization to the fast-paced regulation changes since 2015. We have mechanical, electrical and plumbing (MEP) engineering design experience in servicing buildings that prioritize the best possible growing conditions like temperature control, humidity, dynamic lighting, airflow, water and ventilation for your crop.

Contact us today to learn how Dialectic Engineering can help build your cannabis grow facility from the ground up.